SMT & THT Production Line Solutions

Streamlined solutions covering prototyping, small-batch builds, and full mass-production — all configured to your exact requirements.

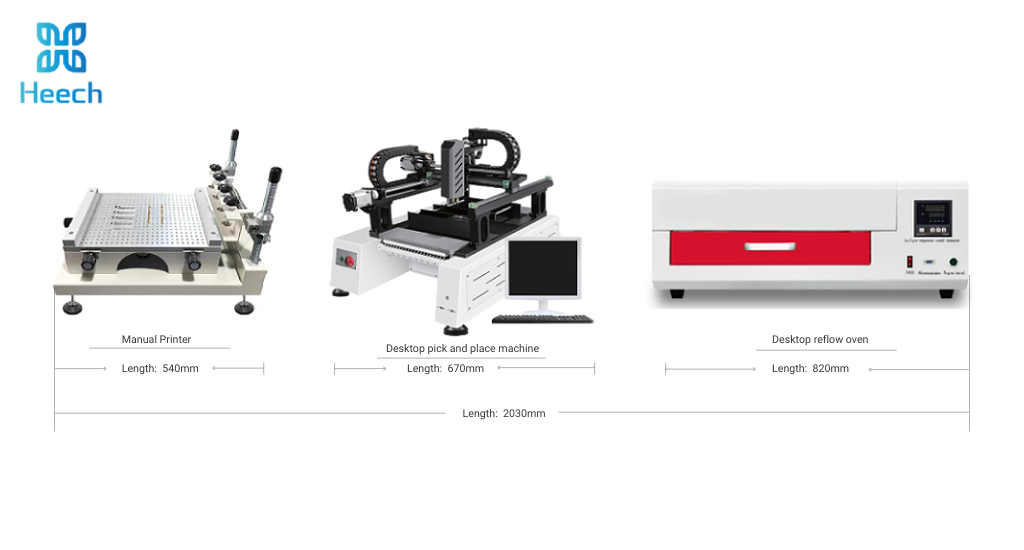

Prototyping

Solution 1

Desktop SMT Production Line – Ideal for Prototyping and Small-Batch Production

This compact desktop production line integrates pick-and-place machine HC-DP240, manual solder paste printer HC-3040H, reflow oven HC-RF3036. This line is ideal for electronics manufacturers, EMS providers, OEM/ODM factories, and startups seeking a reliable, compact, and fully integrated solution for small-scale production and rapid prototyping.

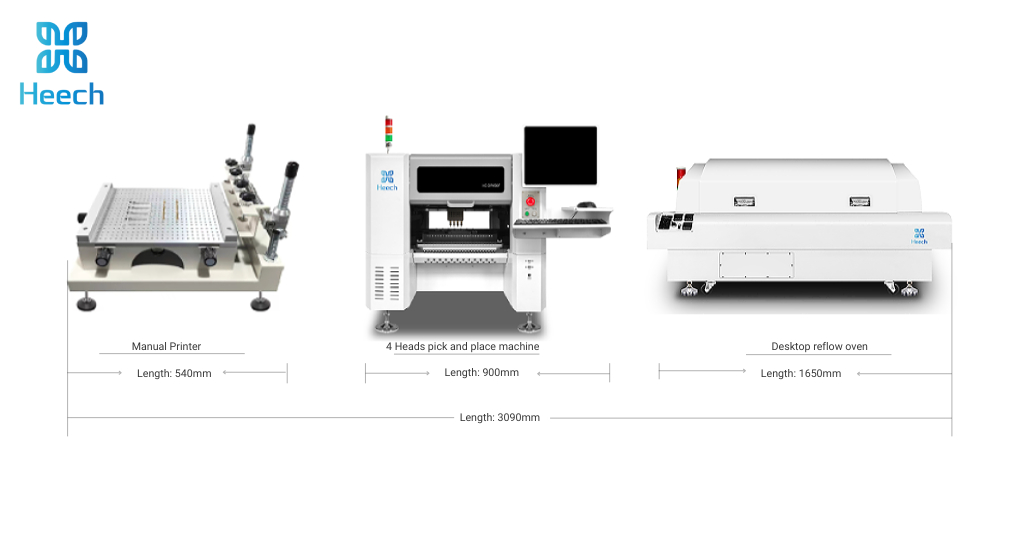

Small-Batch SMT Production Line

Solution 2

Desktop SMT Production Line – Ideal for Small-Batch Production

This compact desktop production line integrates pick-and-place machine HC-DP450, manual solder paste printer HC-3040H, reflow oven HC-RF306. This line is ideal for electronics manufacturers, EMS providers, OEM/ODM factories, and startups seeking a reliable, compact, and fully integrated solution for small-scale production.

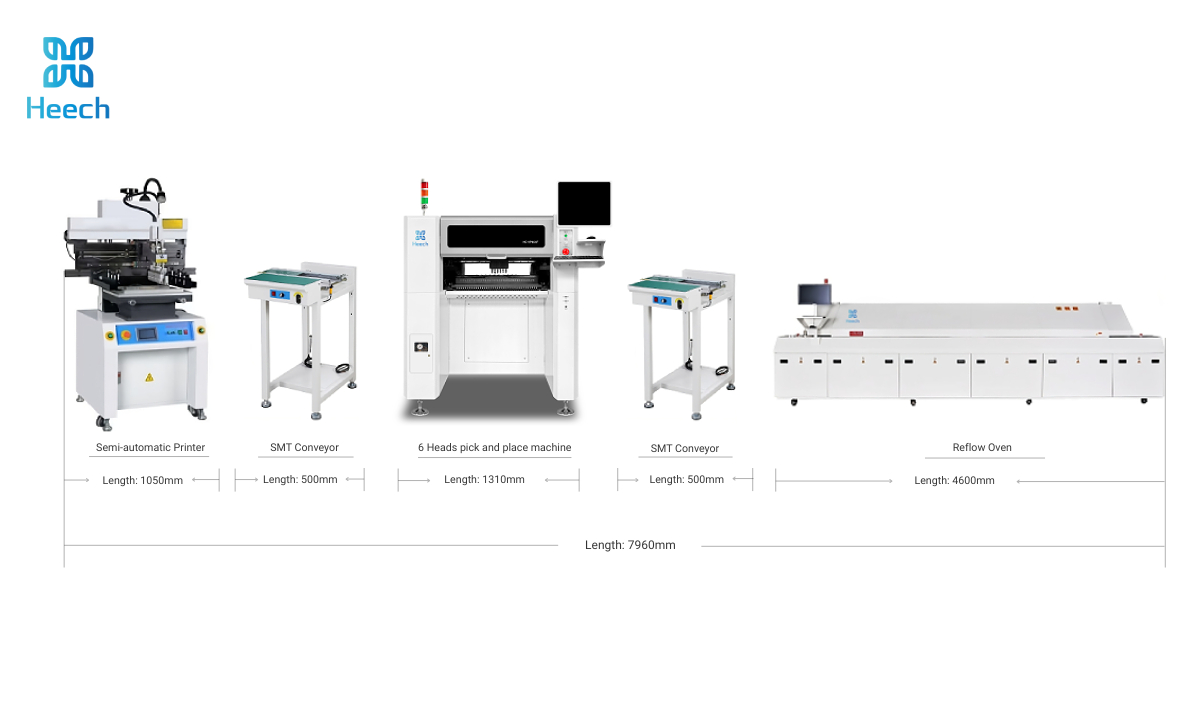

Small to Medium SMT Production Line

Solution 3

High Speed PCB Assembly Line-Ideal for Small-Midium Batch Production

This compact desktop production line integrates semi-automatic solder paste printer HC-PR650, conveyor, full automatic pick-and-place machine HC-VP664F, reflow oven HC-RF8820D. It is ideal for electronics factories with growing production demands—such as EMS providers, OEM/ODM factories, and brand owners—requiring reliable throughput and consistent quality while maintaining cost control.

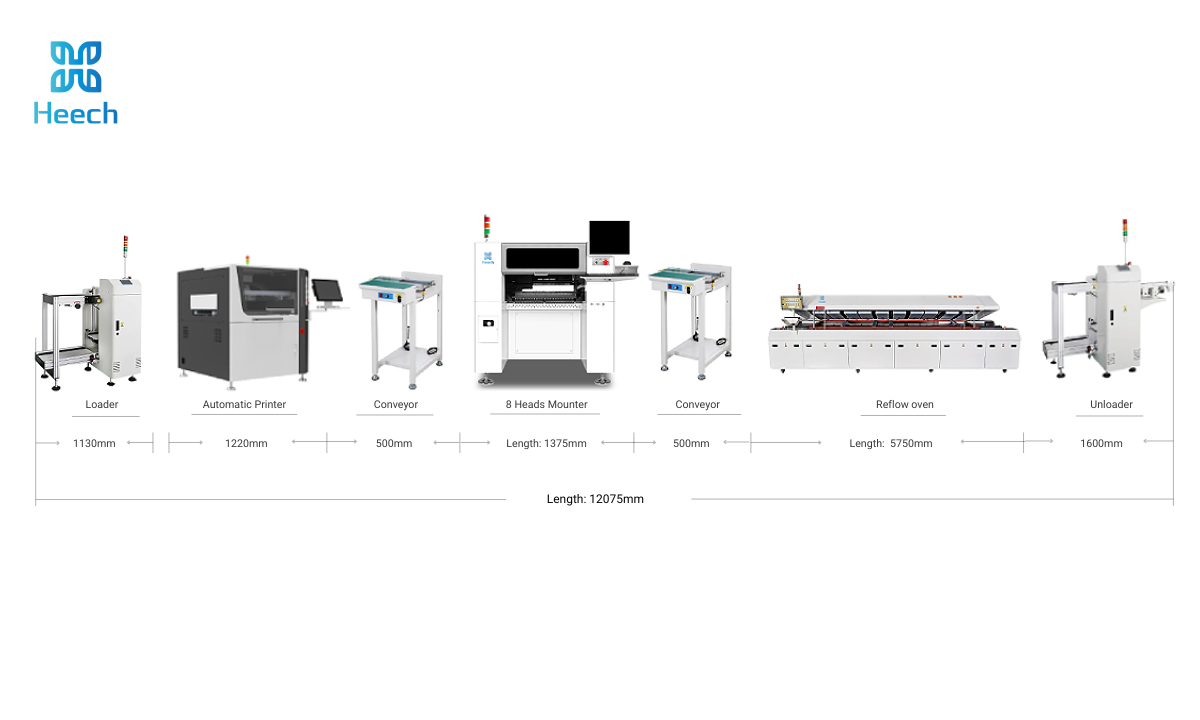

Fully Automatic SMT Production Line for Mass Production

Solution 4

Fully Automatic SMT Line - Ideal for Medium-Large Batch PCBA Production,

This comprehensive solution integrates loader, full automatic solder paste printer, conveyor, 8 heads pick and place machine , 10 zones large-scale reflow oven, and unloader into one seamless and fully automated workflow. This production line represents the highest level of automation in modern SMT manufacturing, offering complete, intelligent, and efficient solutions for medium-large batch PCBA assembly.

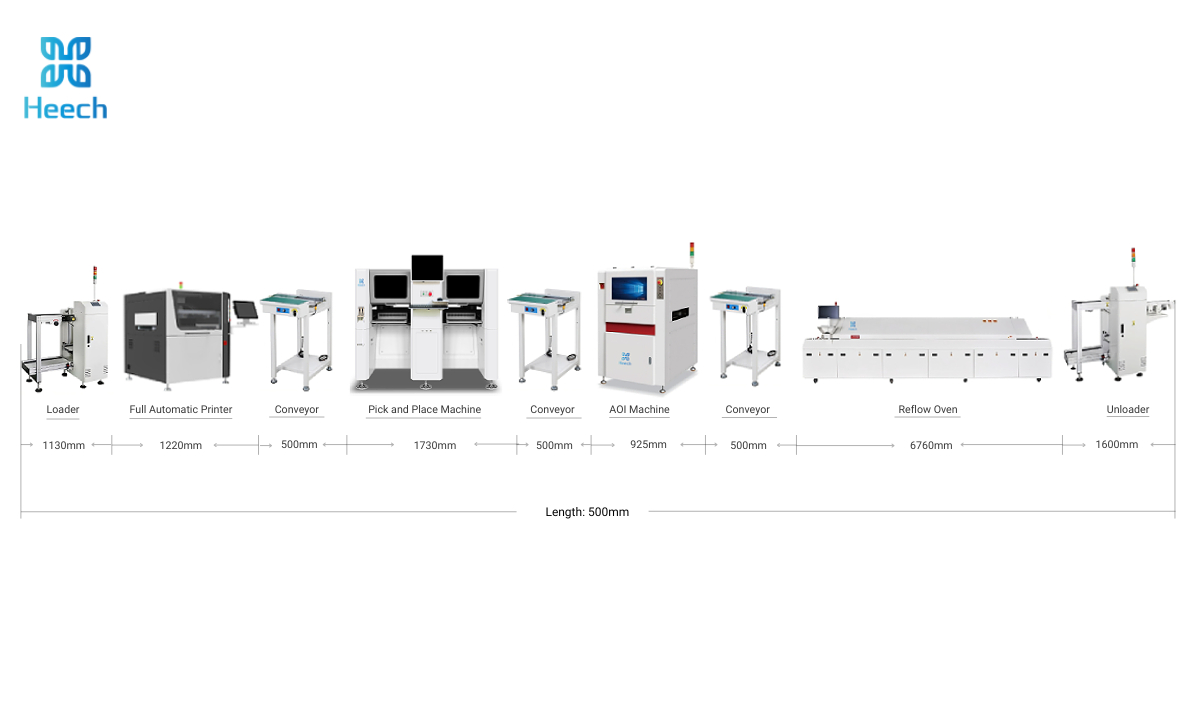

Fully Automatic SMT Production Line for Mass Production

Solution 5

Fully Automatic SMT Production Line-Intelligent Manufacturing for Mass Production

This comprehensive solution integrates loader, full automatic solder paste printer, conveyor, 8 heads pick and place machine , Online AOI Inspection Machine, 12 zones large-scale reflow oven, and unloader into one seamless and fully automated workflow. This production line represents the highest level of automation in modern SMT manufacturing, offering complete, intelligent, and efficient solutions for large-scale industrial applications.

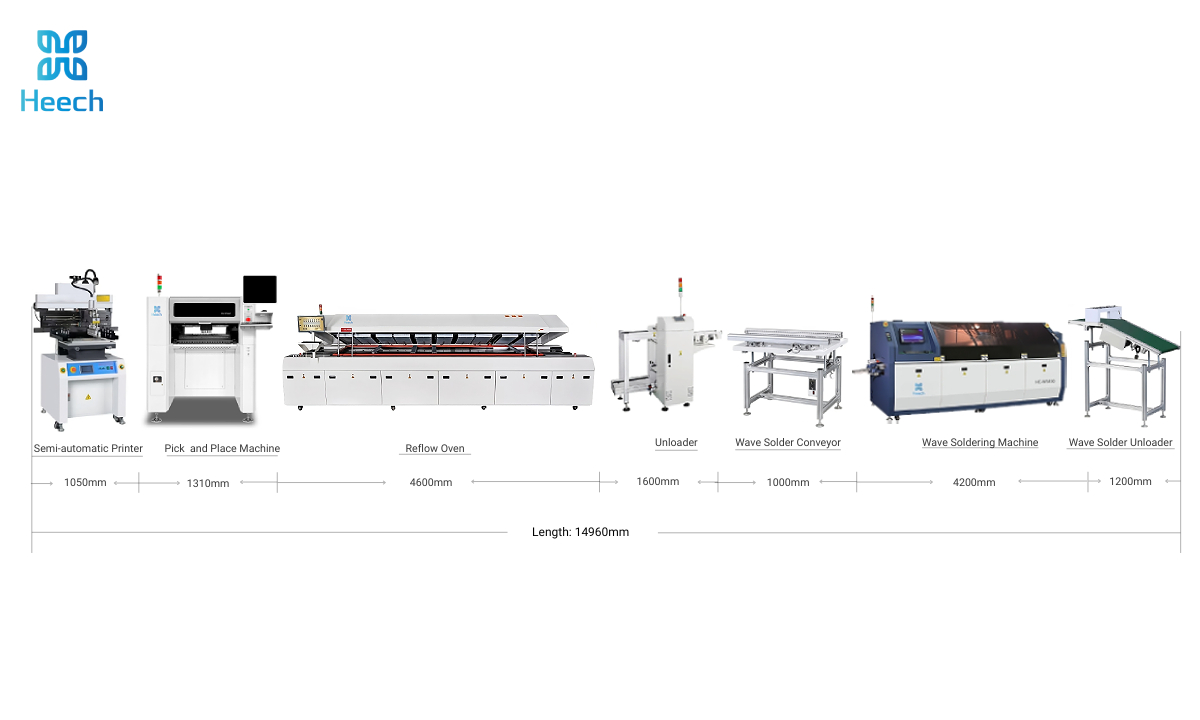

SMT + THT Hybrid Production Line

Solution 6

Fully Automatic Production Line-Solution for both SMT and THT processes within one system.

This line combines the precision of SMT with the reliability of THT soldering,integrates semi-automatic solder paste printer, pick and place machine, reflow oven, unloader, wave solder conveyor, wave soldering machine, wave solder unloader.

The SMT + THT hybrid production line is designed to handle both surface-mount and through-hole components within one integrated workflow. It provides a complete, flexible solution for manufacturers producing mixed-technology electronic assemblies such as power supplies, home appliances, industrial control boards, and automotive electronics.

Frequently Asked Questions

What products and solutions does Heech offer?

Heech provides a full range of SMT and THT production line equipment, including pick-and-place machines, reflow ovens, solder paste printers, solder paste mixers, wave soldering machines, PCB loaders/unloaders, inspection conveyors, AOI systems, and one-stop production line solutions. OEM/ODM services are available.

Which industries and customers can benefit from Heech’s machines?

Our machines are suitable for Electronics Manufacturing Services (EMS) companies, OEM/ODM factories, electronics industrial parks, distributors, and brand owners seeking high-quality SMT/THT equipment.

How does Heech ensure product quality?

Each machine undergoes strict quality inspection and testing before shipment. Certificates and technical documentation are provided to ensure compliance with international standards.

Can Heech assist with line setup and installation?

Yes. Heech offers professional installation guidance, operator training, and technical support to help clients quickly and efficiently set up SMT/THT lines, even if they have limited prior experience.

What after-sale services are provided?

We provide remote technical support, on-site service (where available), spare parts supply, and maintenance guidance to ensure minimal downtime for your production line.

Can Heech customize machines according to specific production requirements?

Yes. Customization is available for line layout, machine specifications, and integration with existing production lines to meet clients’ unique needs.

What types of production lines does Heech provide?

Heech offers a complete range of SMT and THT production lines, including desktop lines for prototyping, small to medium-scale production lines, fully automatic high-volume lines, and hybrid SMT + THT mixed-assembly solutions.

Can Heech provide one-stop turnkey solutions?

Yes. We specialize in providing one-stop SMT/THT line solutions—from design, equipment configuration, logistics, installation, and training to after-sales technical support.

Can your production lines be customized?

Absolutely. Each production line can be customized according to product type, production capacity, factory layout, and customer budget.

What is the difference between desktop, small-to-medium, and fully automatic lines?

Desktop lines are designed for prototyping and small-batch runs. Small-to-medium lines provide balanced efficiency and flexibility, while fully automatic lines support 24-hour high-volume production with minimal labor.

Can SMT and THT equipment be combined in one line?

Yes. Our hybrid SMT + THT production line integrates reflow and wave soldering processes, suitable for mixed-assembly PCBs such as power supplies and control boards.

What is your warranty policy?

We provide a 1-year warranty for all main equipment and lifetime technical support. Spare parts are available at factory price after the warranty period.

Do you offer CE certification?

Yes. Our products are CE-certified, and our production management complies with ISO standards.

How long is the delivery time?

Standard machines are usually ready within 5–7 working days. Complete production lines may take 7–10 days depending on configuration.

What are your payment terms?

Common terms include 30% advance payment and 70% balance before shipment.

Can you arrange shipment to my factory?

Yes. We provide door-to-door logistics service, including sea freight, air freight, and inland transportation.

How do you provide technical support after delivery?

We offer 24/7 online technical support via email, video call, and remote diagnosis. For complex cases, we can dispatch engineers to your site.

What if spare parts are needed urgently?

We keep sufficient stock of common spare parts to ensure prompt supply. For overseas clients, express delivery is arranged immediately upon request.

How can I get software or firmware updates?

All software updates are provided free of charge during the lifetime of the machine. Customers can download updates or receive them via remote support.

Contact Us

If you are planning to build or upgrade your SMT/THT production line, our engineering team can provide a free layout design, equipment configuration, and quotation within 24 hours.

Get In Touch

Chenzhou Heech Electronic Equipment Co.,Ltd

- Building 11, 2nd Industrial Zone of Songgang, Bao’an District, Shenzhen , Guangdong.

- serena.deng@heechsmt.com

- +86 15773596026

- 15773596026